M Series

Bodor M Series: Flagship Fiber Laser Metal Tube Cutting Machine

The Bodor M Series is a flagship fiber laser metal tube cutting machine. It is a groundbreaking innovation in the industry, ushering in a new era of four chucks.

Key Features:

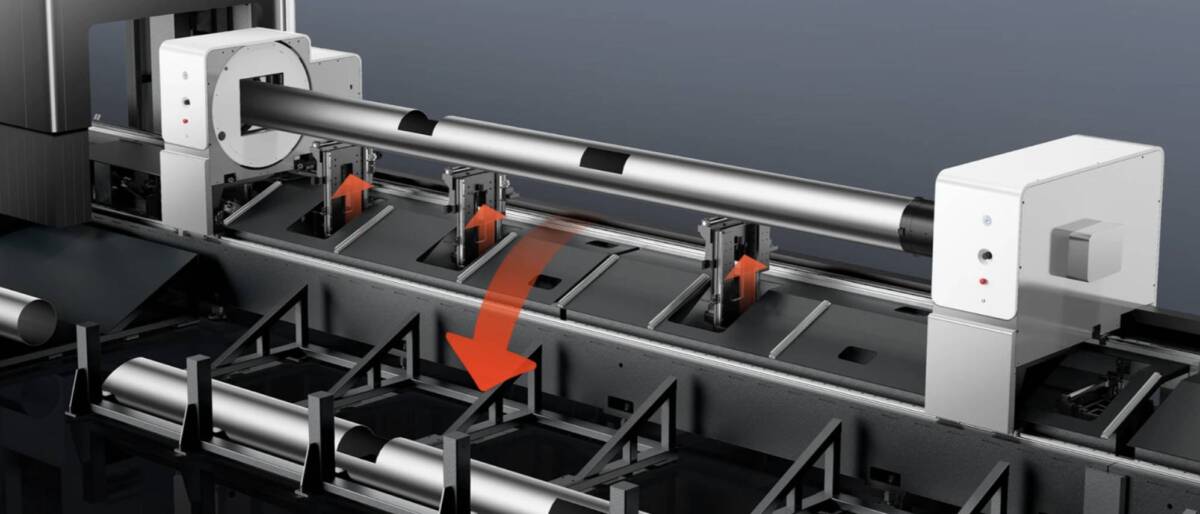

Synchronous Dual Process with Four Chucks: The M5’s 4-chuck mechanism enables hands-free, high-precision cutting, eliminating the need for manual intervention. This creates a secure, low-cost operating environment, keeping personnel safe and reducing labor expenses.

Strong Loading Capacity: The M5 handles diameters up to 530 mm, making it ideal for heavy-duty processing and diverse industrial needs.

0 Excess Material Waste: The M5 maximizes material utilization during operations, cutting scrap and boosting cost-effectiveness.

Simultaneous Cutting, Loading, and Unloading: When cutting tubes, it can simultaneously initiate a new round of loading or finish the previous unloading, bringing about an unprecedentedly efficient and smooth processing experience.

Intelligent Cutting Modes Switching: According to different working conditions, the four chucks achieve intelligent pairing and automatically switch processing modes, perfectly adapting to any processing scenario to ensure optimal processing results.

Ultra-Large Cutting Range: Featuring the square-round structure chuck, the M Series allows the cutting of round tubes with a maximum diameter equal to the maximum side length of square tubes, offering users more flexible processing options.

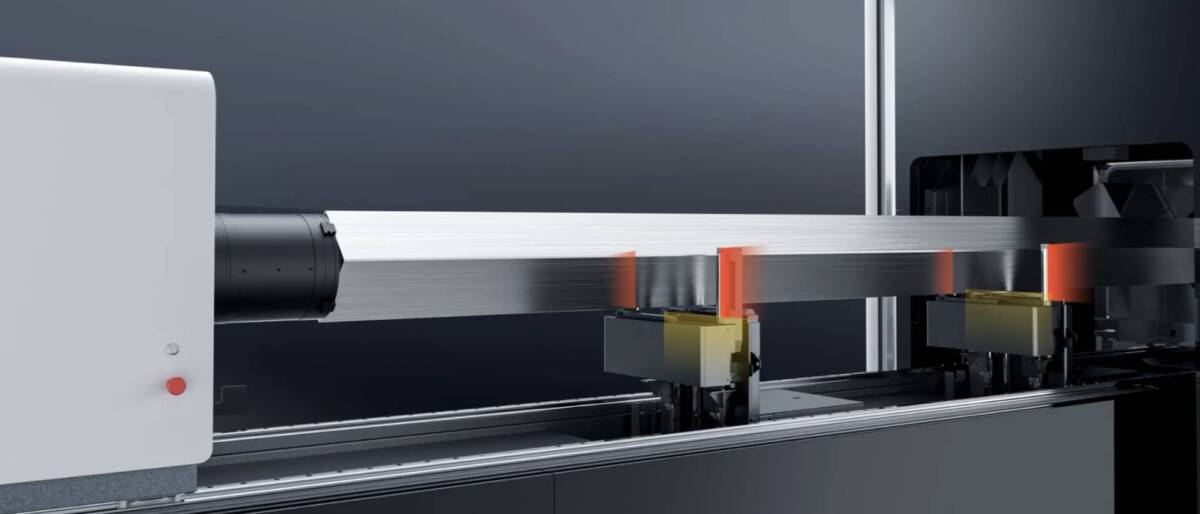

Over Edge Protection for Tubes: Self-developed servo-following sensors and path avoidance algorithms can accurately sense obstacles in the position changes of the tube edges, and plan the obstacle avoidance route in advance to reduce the risk of laser head collision significantly.

Weld Seam Identification Flexible Adaptation: Equipped with a high-sensitivity ultra-clear camera and AI self-learning function, it precisely identifies weld seam positions, enabling cutting avoidance.

M Series Product Performance

| Model | Maximum weight of pipe | Maximum length of pipe | Maximum speed of chuck feeding shaft | Maximum speed of laser head moving axis | Maximum acceleration of chuck feeding shaft | Maximum acceleration of laser head moving axis | Maximum speed of Z axis | Repeat Positioning Accuracy | Positioning Accuracy | Shortest remaining material length |

|---|---|---|---|---|---|---|---|---|---|---|

| M500 | 3000kg | 12000mm | 35m/min | 35m/min | 0.5G | 0.5G | 25m/min | ±0.03mm/m | ||

| M350 | 800kg | 9200mm | 80m/min | 60m/min | 1G | 0.6G | 60m/min | 0.06mm/m | 0.04mm/m | Zero Remaining |

| M230 | 300kg | 6500mm | 110m/min | 60m/min | 1G | 0.6G | 60m/min | 0.06mm/m | 0.04mm/m | Zero Remaining |