CT SERIES

Bodor CT Series: Combo Sheet & Tube Laser Cutting Machine

The Bodor CT Series is a versatile machine that combines sheet and tube cutting capabilities in a single unit, making it a cost-effective solution. It is manufactured to meet stringent European standards, ensuring superior quality and reliability. The series also comes with a protective enclosure for added safety.

Key Features:

Efficient Production: Fast transmission speed and a high-performance bus servo motor increase processing efficiency.

Cost-Effective: Minimizes the need for multiple machines by offering both sheet and tube cutting.

Cutting Parameter Auto-Match: Visual comparison of sample parts and automatic matching of cutting parameters enhance cutting quality and reduce labor costs.

3rd-Generation Mortise-and-Tenon Welding Bed Frame: Offers increased rigidity (by 30%) and enhanced structural strength (by 25%).

Aerospace Aluminum Beam: Lightweight (30% reduction) with high structural strength (25% enhancement).

Intelligent Collision Avoidance: Self-developed servo-following sensors and path avoidance algorithms reduce the risk of laser head collision.

Fast Pneumatic Chucks: Enables clamping in as fast as 2 seconds, simplifying disassembly and maintenance.

Intelligent Gas Pressure Controlling: Achieves real-time detection and adjustment of air pressure for consistent cutting.

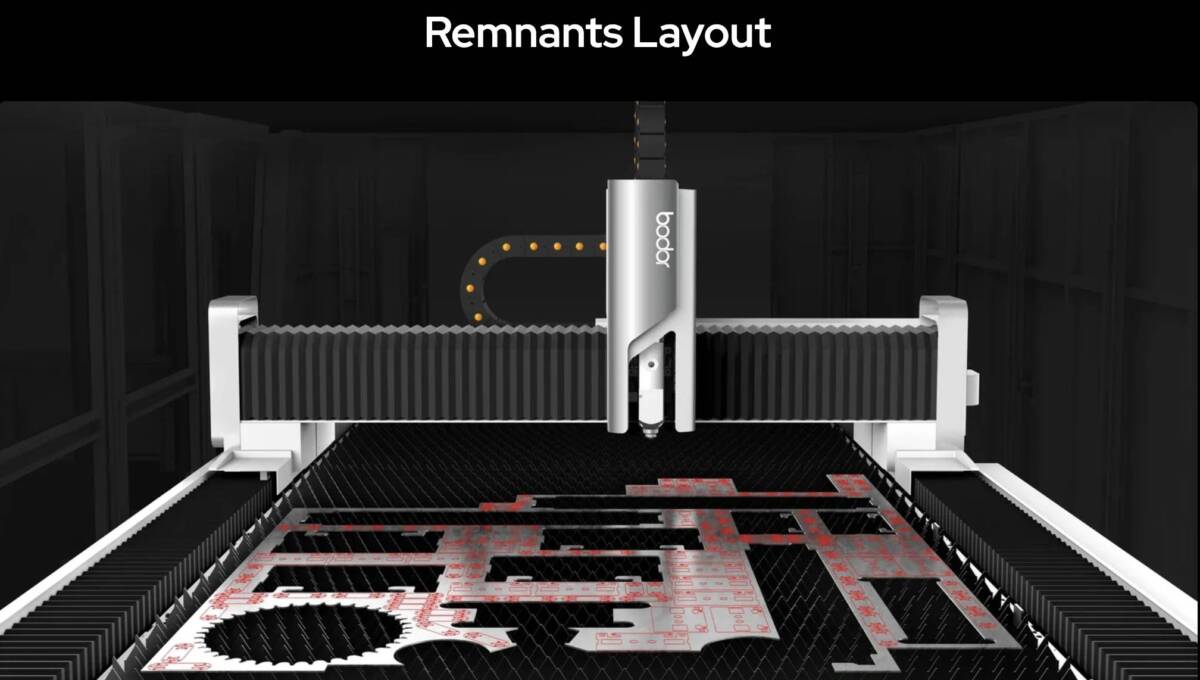

Remnants Layout: By taking a photo of remnants with your phone and uploading the image, you can make the remnant layout a one-click task as the system automatically identifies and quickly locates the corners.

Mineral Cast Anti-Burn Plate: Heat-resistant and non-conductive, reducing deformation and ensuring a long lifespan.

CT Series Product Performance

| Feature | Specification |

|---|---|

| Working Area | 3048mm*1524mm |

| Max. Linkage Speed | 100m/min |

| Max. Acceleration | 1.0G |

| Z-Axis Travel | 370mm |

| Positioning Accuracy | ±0.05mm/m |

| Repositioning Accuracy | ±0.03mm |

| Table Load Bearing | 1-6kW:911kg(25mm) |

| Overall Dimensions | 9700mm*3600mm*2400mm |