ROCUT SERIES

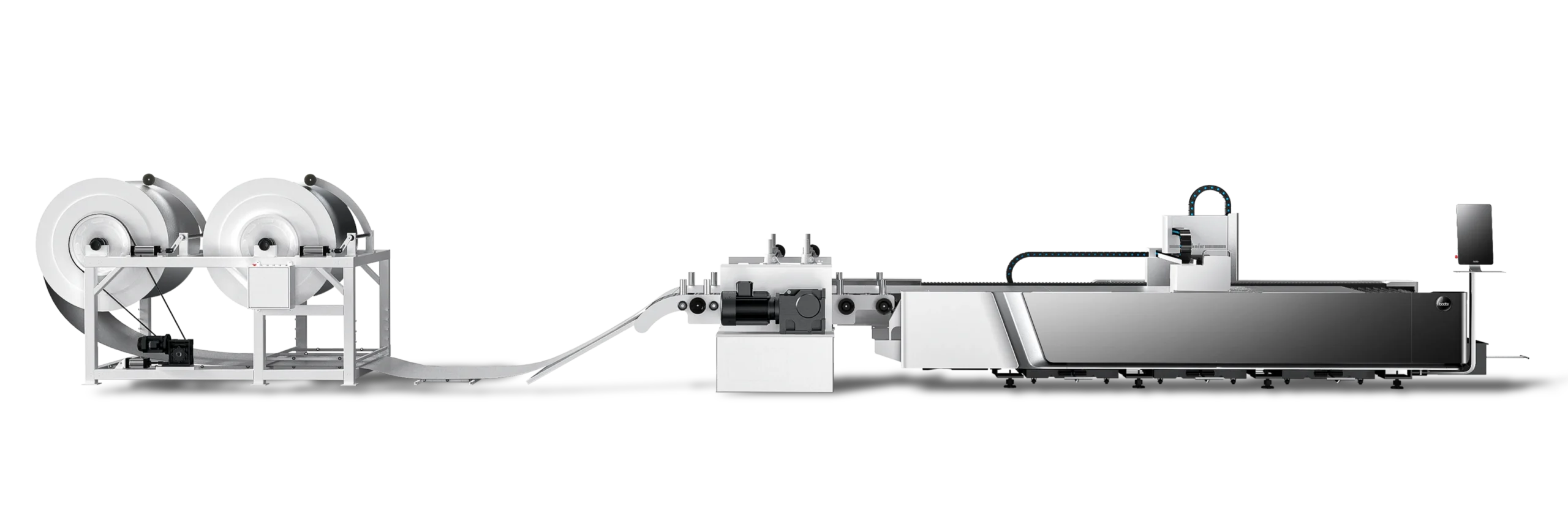

Bodor R Series: Steel Coil Laser Production Line

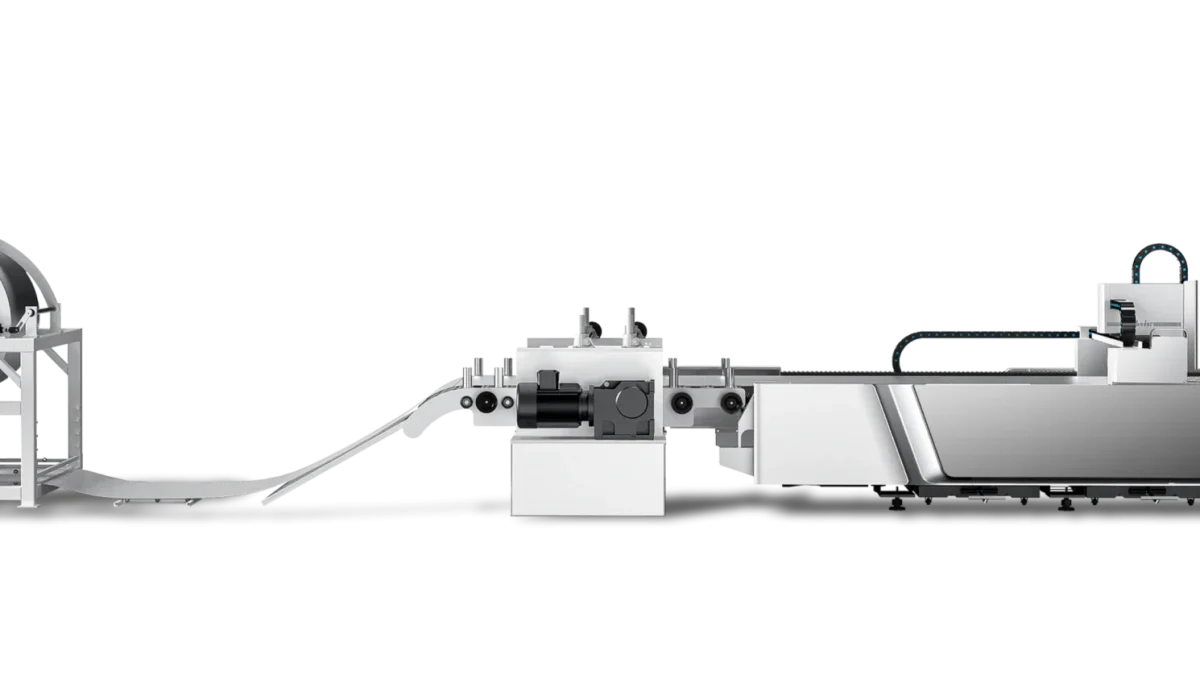

The Bodor Rocut Series Steel Coil Laser Production Line integrates uncoiling, leveling, and cutting. It is designed for steel coil manufacture, offering one-stop functioning for complete steel coil processing.

Key Features:

-

Automatic Coil Processing: Uncoiling, leveling, and cutting are completed in one step.

-

Lower Material Costs: Continuous nesting optimizes coil materials, reducing scrap and component costs.

-

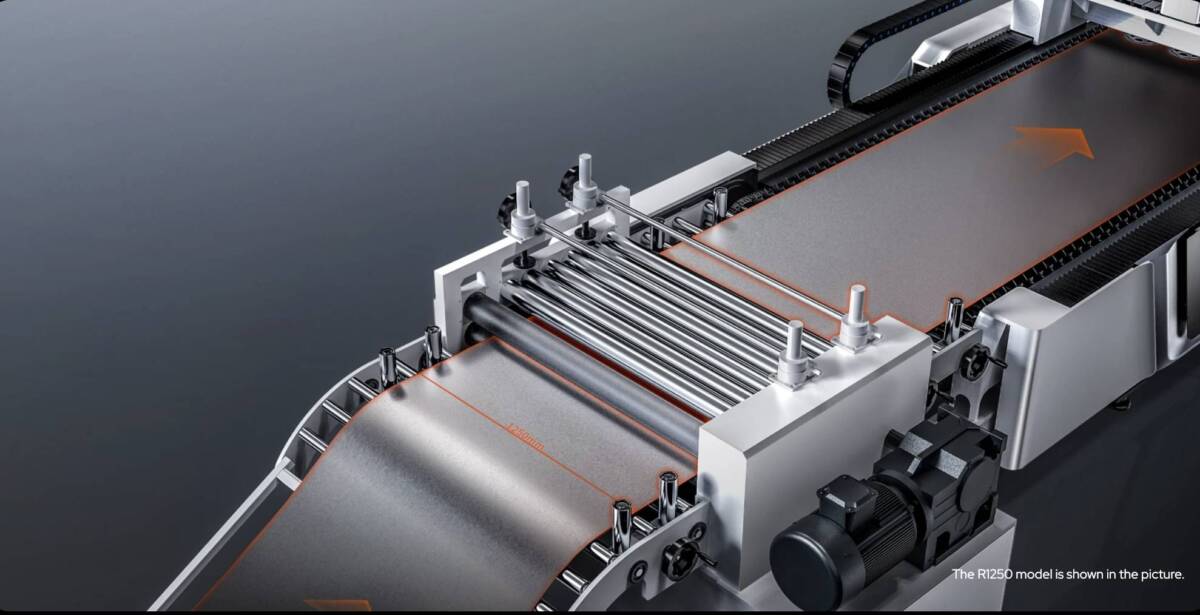

High Precision: Misalignment correction function ensures precise coil cutting.

-

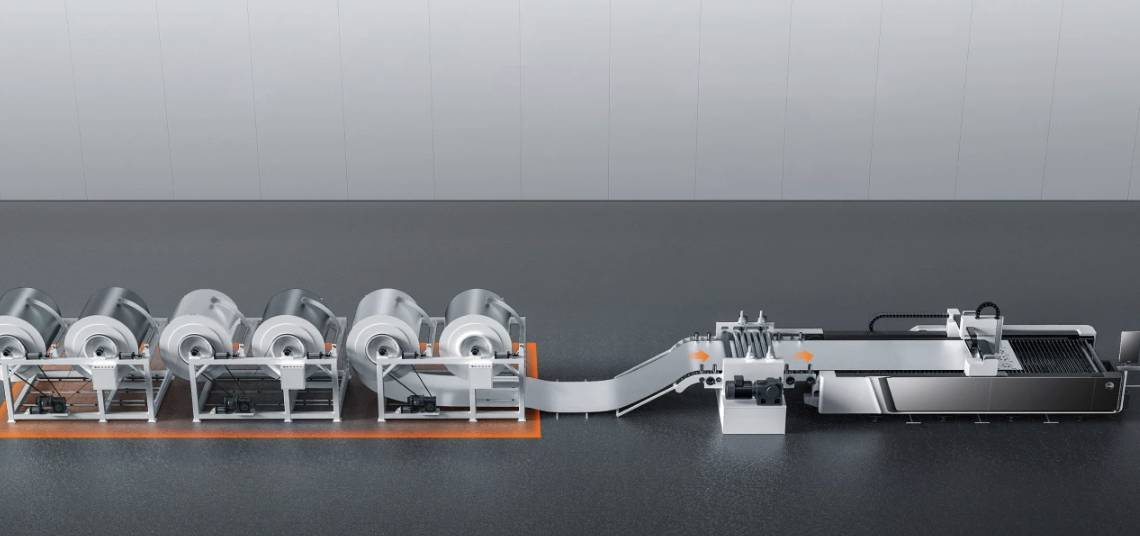

6 Uncoiling Stations: Allows for loading various materials and thicknesses without stopping for material changes.

-

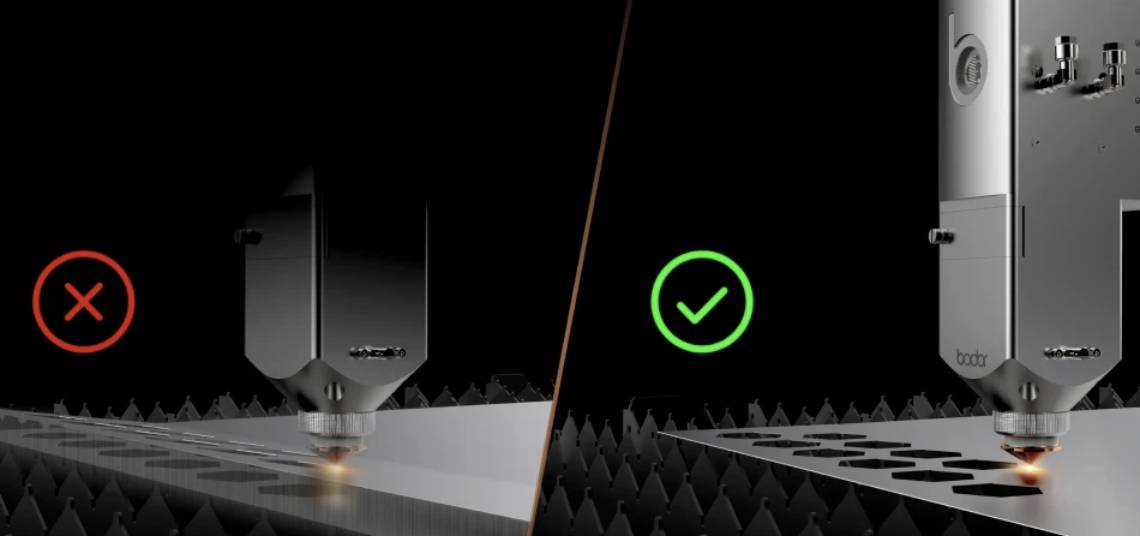

Sheet Edge Anti-Vibrating Stable Cutting: Adapts to the high-frequency vibration of thin sheets, ensuring stable cutting quality and efficiency.

-

(Optional) Laser Scanning Cutting: High energy absorption rate within the cutting area.

-

Laser Head Intelligent Collision Avoidance: Self-developed servo-following sensors and path avoidance algorithms sense obstacles in real-time and plan obstacle avoidance.

Rocut Series - Product Performance

| Model | Working Area | Max. Linkage Speed | Max. Acceleration | Z-axis travel | Positioning Accuracy | Repositioning Accuracy | Dimensions | Table Load Bearing |

|---|---|---|---|---|---|---|---|---|

| R1250 | 3048mm*1250mm | 90m/min | 1G | 100mm | ±0.05mm/m | ±0.03mm | 14600×2575×2260mm | 110kg |

| Rocut3 | 3048mm*1524mm | 90m/min | 1G | 100mm | ±0.05mm/m | ±0.03mm | 14855×2940×2380mm | 110kg |