Repair Services: Keeping Your Bodor Machinery Running Strong

Downtime is a major problem for any business. It slows down production, costs you money, and can hurt your reputation. At AMS Inc., we understand that your Bodor laser machine is the heart of your operation, and we’re here to keep it healthy. Our repair services are designed to be fast, precise, and reliable, getting you back to work with minimal disruption.

Our technicians are more than just repair people; they are factory-trained specialists with deep expertise in Bodor equipment. They can diagnose and fix a wide range of issues, ensuring your machine performs at its best. We’re committed to providing quick, lasting solutions, helping you maintain peak efficiency for the long haul.

Our Multilingual Team: Serving a Global Market

In today’s global economy, clear communication is essential. Our team includes employees who are fluent in multiple languages. This allows us to work smoothly with foreign suppliers and international partners. Whether we’re discussing technical details with a manufacturer or providing support to a client overseas, our linguistic abilities help ensure every conversation is clear and effective. This makes for a more comfortable and reliable experience for all our clients, no matter where they are located.

Our Repair Expertise: Specialized Knowledge for Your Machines

We specialize in the intricate repair and maintenance of Bodor’s world-class machinery. Our team’s in-depth knowledge of each machine series allows us to fix problems with confidence and accuracy.

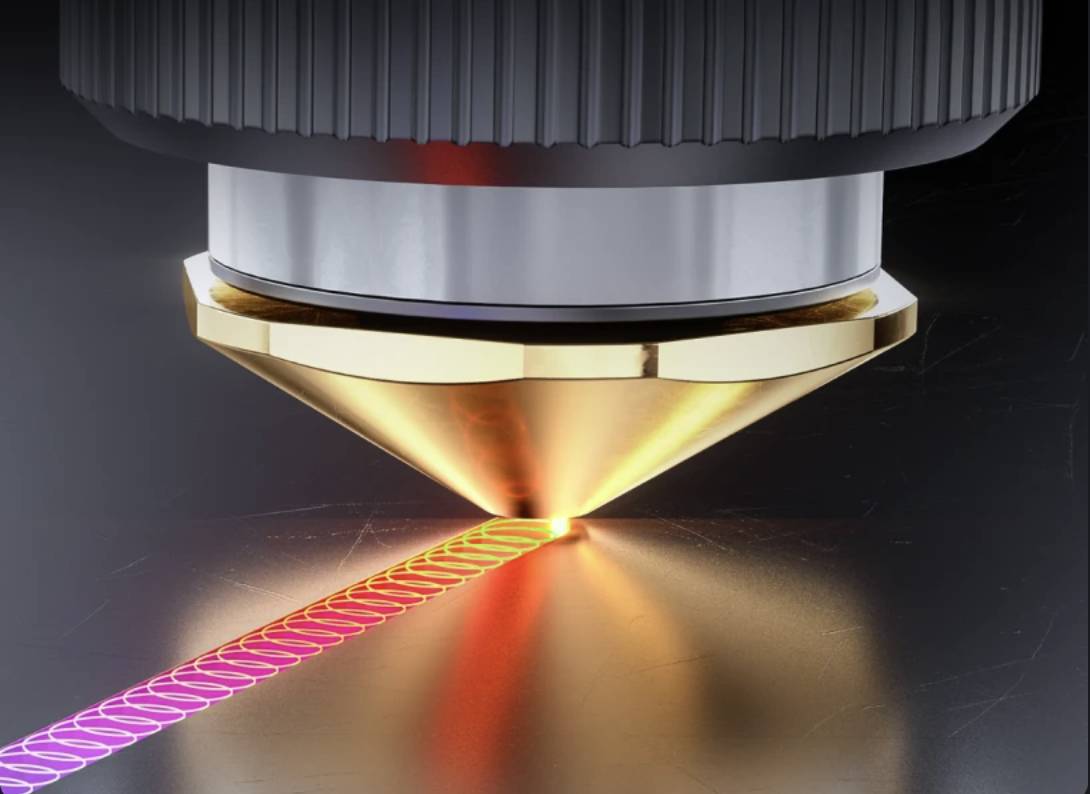

- Laser Cutting Machines (P, C, Dream, A, B, H, G, L, I, and Rocut Series): These machines are crucial for high-speed, precise cutting. We’re experts at troubleshooting issues with the optics, controls, and mechanics that are essential for top performance. We make sure every cut is clean and accurate.

- Laser Tube Machines (T, K, M, and Q Series): These machines are key for cutting tubing with complex designs. Their unique chuck and rotation systems require specialized repair skills. We can calibrate and fix these complex systems so your machine maintains its precision for any job.

- Sheet-Tube Laser Cutting Machines (CT and AT Series): These versatile machines can cut both sheets and tubes. Our technicians have the dual expertise to handle both parts of the machine, making sure your machine’s flexibility is always available.

- Profile Laser Cutting Machines (U 10 and HCut Series): These are designed for high-efficiency cutting. We are skilled in repairing their specialized feeding systems and ensuring the laser path is perfectly aligned for consistent, high-quality results.

Laser Welding Machines (Air and Pro Series): Laser welding requires extreme precision. Our team is trained to fix problems with the laser source, welding head, and control systems to ensure your machine delivers strong, clean, and consistent welds.

Our Core Commitments: The AMS Inc. Advantage

When you choose AMS Inc., you get a partner dedicated to your success. Our service is built on key principles to give you the best possible experience.

- Expert Diagnosis: Our technicians use the latest diagnostic tools and have a deep understanding of Bodor’s software and hardware. This allows them to quickly find the root cause of any issue, avoiding guesswork and making repairs more efficient.

- Preventative Maintenance: We believe in being proactive. We can set up a maintenance schedule that includes regular inspections and part replacements. This keeps your machines running smoothly, extends their life, and saves you time and money.

- Genuine Parts: We only use authentic Bodor parts for all our repairs. This ensures the highest quality, perfect compatibility, and maintains your machine’s integrity. Using genuine parts also helps keep your equipment under warranty.

- Comprehensive Service Reporting: After every service visit, we give you a detailed report. This report explains the work done, lists any new parts, and offers recommendations for future maintenance. This transparency keeps you fully informed about your equipment’s condition.

Training and Support: We offer specialized training to help your team confidently operate and perform basic maintenance on your machinery. Our dedicated support staff is always ready to answer your questions and provide assistance, so you’re never left in the dark.

The AMS Inc. Repair Process: Simple and Efficient

We’ve made our repair process as straightforward as possible. From your first call to the final follow-up, you can expect a professional and transparent experience.

- Initial Contact: Call us with your machine issue, and our service coordinator will get all the necessary details.

- Remote Diagnosis: We often start with a remote diagnosis, using your team’s input or machine data to identify the problem and prepare the right parts before we even arrive.

- On-Site Service: A certified technician will be dispatched to your facility with all the tools and parts needed. They will perform a thorough, on-site diagnosis and begin the repair.

- Testing and Calibration: After the repair is finished, the technician will run tests and recalibrate the machine to make sure it’s working perfectly.

Final Review and Follow-Up: The technician will go over the work with you, provide the service report, and answer any final questions. Our support team will also follow up to ensure you are fully satisfied with the repair.

How to Schedule a Repair

Ready to get your machine back in top shape? Simply contact our service department to discuss your repair needs. You can reach us by phone, email, or by filling out the contact form on our website. We will work with you to schedule a convenient time for a technician to visit your facility and get your machine back in perfect working order. Let AMS Inc. be your trusted partner in maintaining the peak performance of your Bodor machinery.